Air Cleaning & Heat Recovery

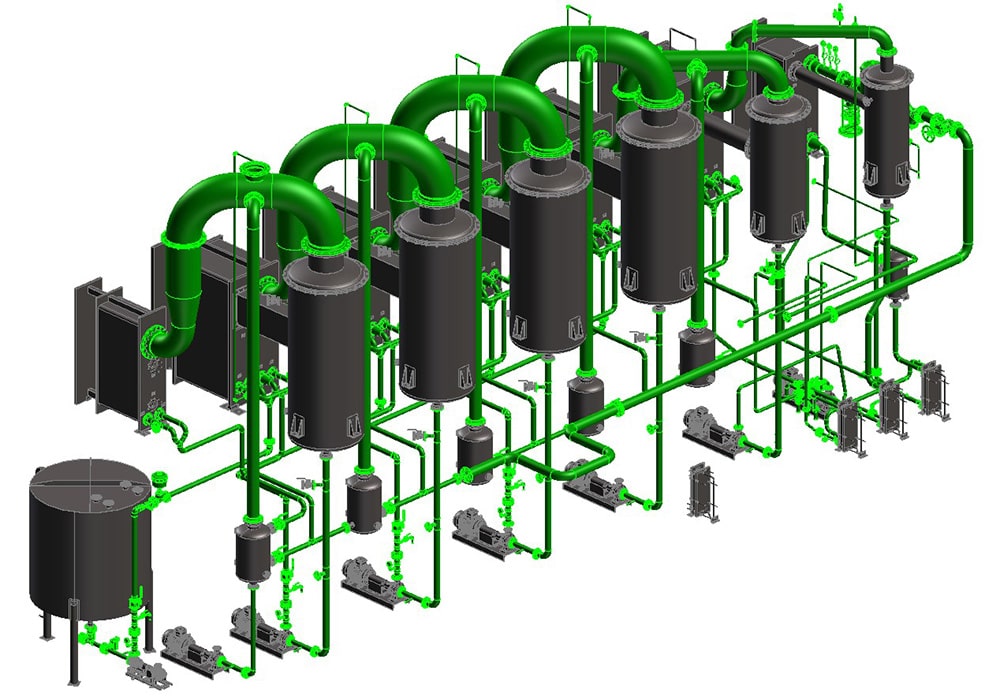

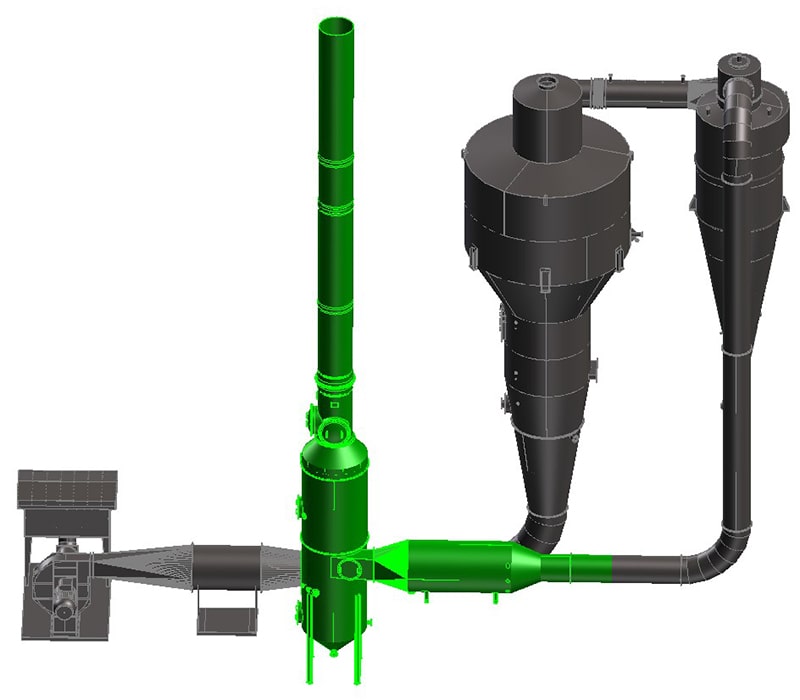

We continuously design with your business in mind to prevent or minimize emissions. Burning a gas will always cause the formation of nitrogen oxides, we cannot avoid this, but we always strive for the opportunity of optimal residual heat utilization, heat recovery from the outgoing granulator process air of 200 °C through an air preheater without corrosion problems due to the selected component materials. This heat recovery easily saves 25 - 30% energy.

The process air system is designed to be heated in- or directly by a heat source and a heat recovery unit to ensure the required heat to the granulator. Depending on the combusted system used an emission of greenhouses gases, carbon dioxide and nitrogen oxides could be released

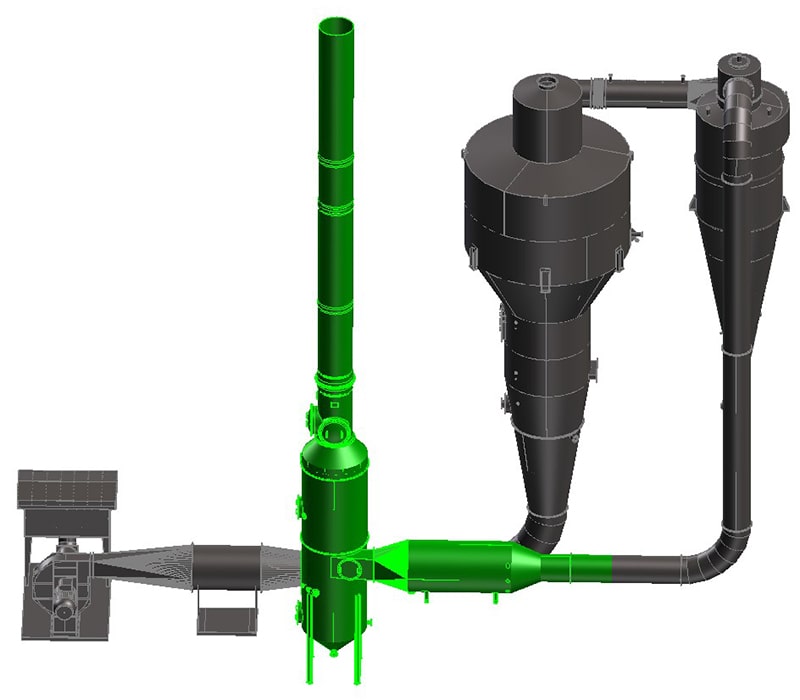

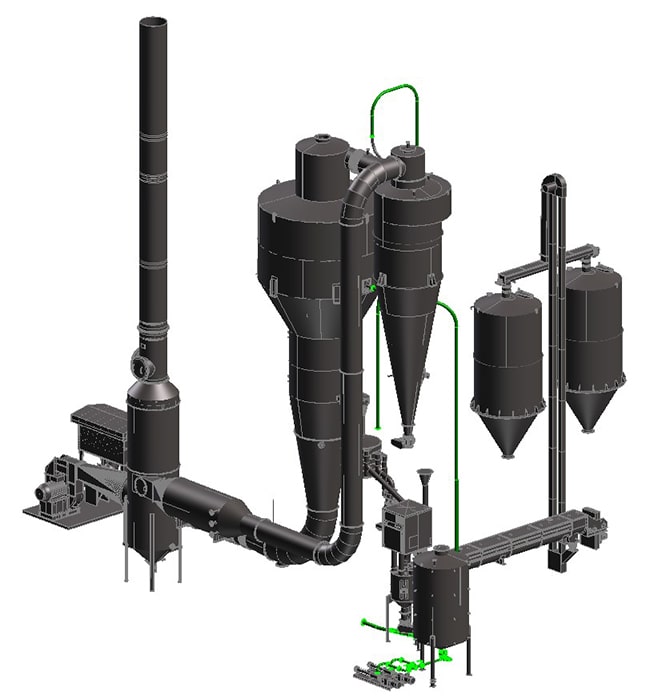

The granulator system uses a cyclone separator to separate the dust particles (>10 microns) from the air, however, there will be always a fraction to pass through, which needs to be captured before the process air leaves the plant. First, the air transfers heat to the incoming stream through a gas/gas heat exchanger and then through a process air cleaning system, CentriField Wet Scrubber, to remove particles and absorb gases, ensuring environmental integrity.